Dosimeter badge services for medical, dental, and veterinary businesses

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.

Reviewed by

Joel H. White, ME, Nuclear Engineering

Dosimetry Consultant

Last Updated: December 16, 2024

Learn about the best materials that block radiation, including lead, concrete, and specialized composites. Discover how different shielding materials protect against alpha, beta, gamma, and neutron radiation, ensuring safety in medical, industrial, and research environments.

While radiation is constantly present in our environment (natural background radiation) and in our bodies, limiting exposure to different types of radiation is incredibly important. Following the three pillars of radiation safety – time, distance, and shielding – is crucial.

In this article, we'll explore the best radiation shielding materials to keep radiation dose “ALARA," or "as low as reasonably achievable." Using this guide, you can feel confident choosing the right radiation shielding materials for your organization.

The United States Nuclear Regulatory Commission (NRC) defines radiation shielding as the "reduction of radiation by interposing a shield of absorbing material between any radioactive source and a person, work area, or radiation-sensitive device." Using or inserting the proper shield can greatly reduce or eliminate the dose received.

Radiation sources can be shielded with solid or liquid radiation shielding material, both of which absorb the energy of the radiation. Different types of radiation interact in different ways with each shielding material, which we'll explore further below.

Although radiation exists throughout our environment and bodies, we must do all we can to reduce unnecessary and excessive radiation exposure. Preventing exposure is critical, as radiation can damage the DNA in human cells.

High doses of radiation can cause acute radiation syndrome (ARS) and cutaneous radiation injuries (CRI). An increased dose of radiation also can potentially cause other harmful effects like cancer in the future.

The shielding materials used depend on the type of radiation they are trying to block. The necessity of shielding materials is based on the principle of attenuation. Attenuation is the degree to which a wave or ray’s effect can be blocked or bounced with the use of shielding materials.

This process of radiation attenuation can be achieved by placing an absorbent or reflective substance between the source emitting radiation and an individual, workspace, or radiation-sensitive instrument. The radiation shielding calculations and properties of any material are presented in terms of the linear attenuation coefficient.

Shielding effectiveness depends on stopping power, which varies with the type and energy of radiation and the shielding material used. Different shielding techniques are, therefore, used depending on the application and the type and energy of the radiation.

In nuclear and materials physics, stopping power is defined as the retarding force acting on charged particles (typically alpha and beta particles) due to interaction with matter, resulting in loss of particle kinetic energy.

The short answer is simply "no." While specific radiation shielding materials are helpful in protecting against particular types of radiation, they may not be effective in protecting against other kinds of radiation.

Shielding is necessary for both directly ionizing radiation and indirectly ionizing radiation. Indirectly ionizing radiation carries no electrical charge and produces ionization by first setting free a charged particle.

The two indirectly ionizing radiations of concern include:

Since lead is an extremely heavy element (heavier than almost 80% of the other elements on the periodic table), it’s a common choice for fabricating radiation shielding products.

Lead is a corrosion-resistant and malleable metal. Its high density (11.34 grams per cubic centimeter) makes it an effective barrier against X-ray and gamma radiation. Other key features include its significant flexibility, exceptional stability, and high atomic number.

Lead is available in various forms (such as sheets, vests, collars, bricks, etc.), making it the best choice for shielding X-rays and gamma rays.

When it comes to choosing the best radiation shielding materials, lead is a solid choice.

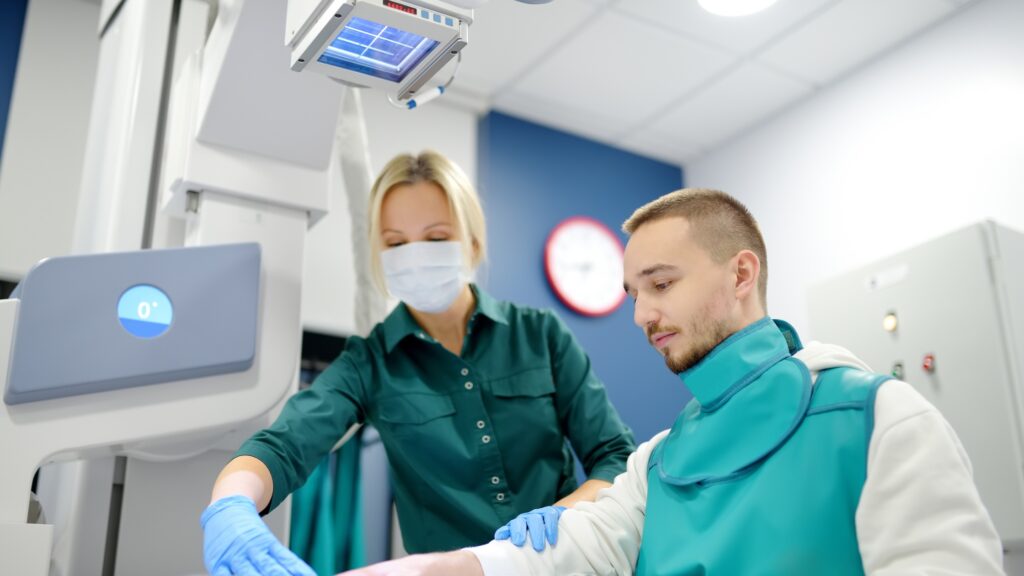

Pure lead is commonly blended with resins and polymeric composite materials to create a flexible lead vinyl film that employees and patients can wear as a radiation shielding material. The lead layers are piled to the required thickness and inserted into the radiation shielding fabric to produce the desired lead thickness.

There are three standard levels of lead equivalent shielding for classic lead radiation shielding clothing: 0.25mm, 0.35mm, and 0.5mm. Lead equivalent products (which are composites that are much lighter than lead) also use these levels. Examples of such products include EarthSafe, Xenolite, and Demron®.

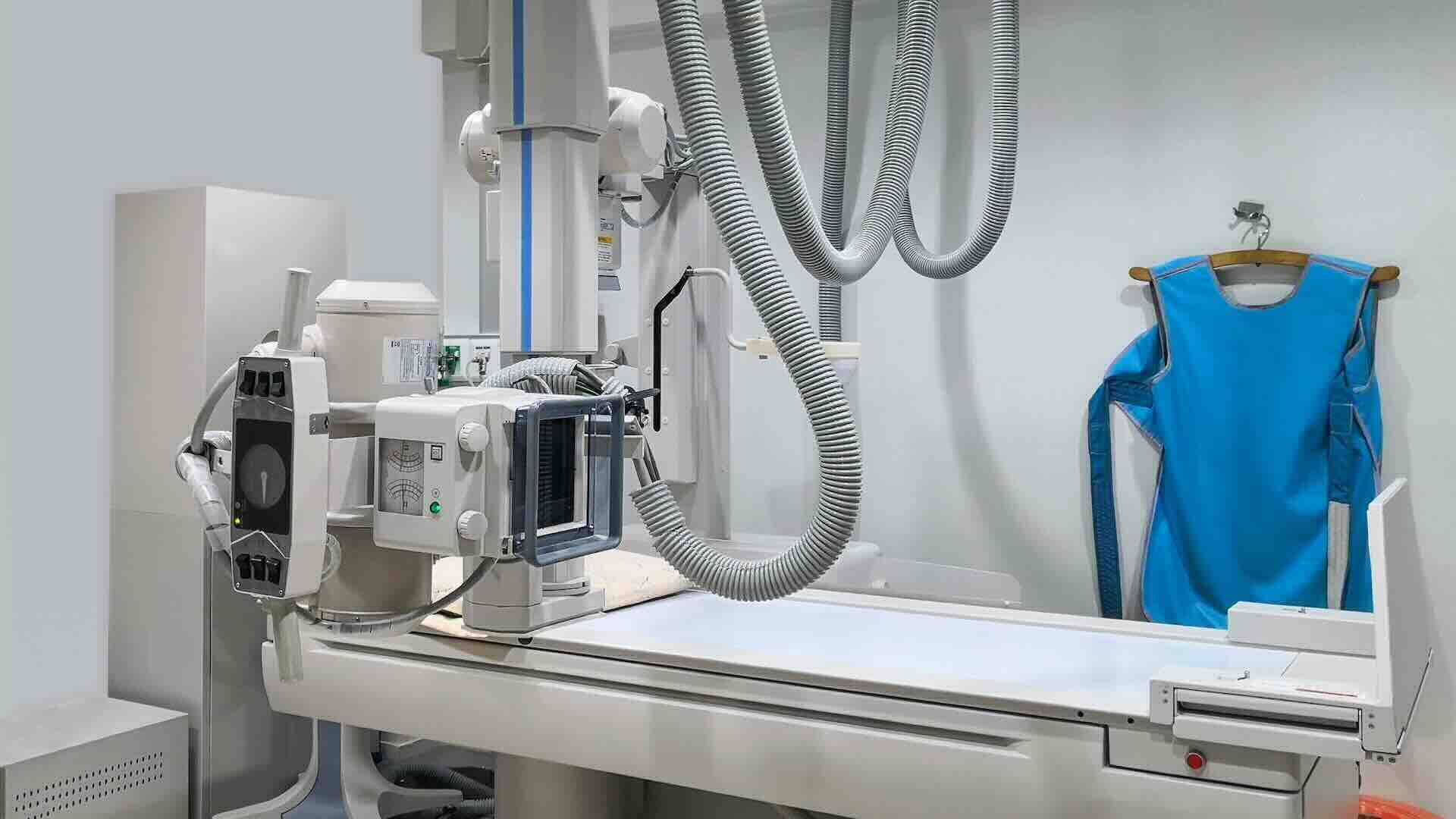

Organizations can also add lead to concrete or cinder blocks for use in wall construction. In X-ray facilities, walls surrounding the room with the X-ray machine may contain lead shielding, such as lead sheets, or the plaster may contain barium sulfate (a dense compound proficient in absorbing gamma radiation). These materials block radiation and limit exposure to radioactive substances outside the enclosed area.

X-ray operators generally view patients through a lead glass screen. If they must remain in the same room as a patient, they may also wear lead aprons.

Lead can be fabricated into different product forms to provide radiation shielding and protection, the most common of which include:

Alpha particles are the least penetrating type of radiation. Even the most energetic alpha particles can be stopped by a single sheet of paper. Alpha particles cannot penetrate the outer layer of dead skin, so they don't pose a risk to humans when the source is outside the body.

Beta particles (electrons) are more penetrating but can still be absorbed by a few millimeters of aluminum. In most cases, low-energy beta particles can be shielded simply by an outer layer of clothing.

However, in cases where high-energy beta particles are emitted, shielding must be accomplished with low atomic weight materials (usually plastic, wood, water, or acrylic glass) to shield out the Bremsstrahlung radiation produced. Bremsstrahlung radiation is the radiation given off by a charged particle (most commonly an electron) due to its acceleration caused by the electric field of another charged particle.

The effectiveness of a shielding material generally increases with its atomic number (called Z), except in the case of neutron shielding. Neutron absorbers and moderators like boron and cadmium more easily shield neutron radiation. Water and hydrocarbons (like polyethylene and paraffin wax) are also used for neutron radiation shielding.

Neutron radiation is not as readily absorbed as charged particle radiation, which makes this type of radiation highly penetrating. In a process called neutron activation, neutrons are absorbed by nuclei of atoms in a nuclear reaction. This process often creates a secondary radiation hazard, as the absorbing nuclei transform to the next-heaviest isotope (many of which are unstable) and then become radioactive and decay.

Finding the right radiation shielding materials doesn't have to be daunting. There are several factors that influence the design, selection, and use of shielding for radioactive material. Considerations such as attenuation effectiveness, strength, resistance to damage, thermal properties, and cost efficiency can affect these choices.

While metals are strong and resistant to radiation damage, they undergo changes in their mechanical properties and can deteriorate in certain ways from radiation exposure.

Conversely, concrete is strong, durable, and relatively inexpensive to produce, but it becomes weaker at higher temperatures, making it less effective at blocking neutrons.

Over time, manufacturers have developed lightweight and lead-free radiation shielding products to provide protection and personal radiation shielding.

One commonly used is Demron®. This flexible fabric can be forged into hazmat suits, blankets, tents, tactical vests, and other personal protection products. Testing by the United States Department of Energy has demonstrated that the lead-free material is effective in reducing the levels of high-energy alpha and beta radiation and low-energy gamma ray radiation.

The lightweight and flexible nature of these types of products makes them ideal for wearable individual protection. They are also easy to clean, maintain, and store.

Radiation Detection Company (RDC) is dedicated to your safety and the safety of all your employees. We have 75 years of experience providing quality dosimetry solutions to over 31,000 organizations worldwide – from local veterinary practices to nuclear power plants.

RDC offers a suite of affordable and comprehensive solutions to fit the needs of any organization, large or small. Please visit our Solutions page to view our extensive offerings.

Do you have a question that we did not address in this article? Please reach out to our Customer Care team, and one of our specialists will be happy to support you.

Different materials are used to block or reduce radiation depending on the type.

These materials help provide necessary shielding in environments like medical facilities, nuclear power plants, and research laboratories.

The most effective radiation shielding depends on the type of radiation being blocked. Lead is the most effective shielding material for gamma rays and X-rays due to its high density and atomic number, which effectively absorbs and attenuates the radiation. Materials rich in hydrogen, such as water, polyethylene, or specially formulated concrete, are most effective for neutron radiation.

In general, the choice of shielding material is based on the specific type and energy of the radiation you're trying to shield and practical considerations such as thickness and weight.

Paper, skin, or even a few centimeters of air can block alpha particles, and plastic, glass, or a few millimeters of aluminum can block beta particles.

Lead, concrete, or several centimeters of dense material can block gamma rays and X-rays. These are highly penetrating forms of electromagnetic radiation that require dense materials to effectively attenuate them.

Alternatively, hydrogen-rich materials like water, polyethylene, or borated materials block neutron radiation.

The most common materials for radiation shielding are lead, lead-free shielding, and lead composites.

Lead is widely used due to its high density and effectiveness in blocking gamma rays and X-rays.

Lead-free shielding alternatives, made from heavy metals like tungsten, tin, bismuth, and antimony, are developed to reduce health and environmental risks.

Lead composites combine lead with materials like rubber, vinyl, or plastic, offering lighter and more flexible options for protective gear and barriers while maintaining adequate radiation protection.

These materials are chosen based on the specific radiation type, application needs, and safety considerations.

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.