Dosimeter badge services for medical, dental, and veterinary businesses

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.

Senior Vice President of Operations & Technical Services

Last Updated: September 25, 2025

Radiation dosimetry services ensure compliance, optimize costs, and protect workers by monitoring exposure with TLD and OSL badges in healthcare, nuclear, and industrial settings. Here's everything you need to know.

Radiation dosimetry is essential for any organization that uses ionizing radiation, from hospitals and research labs to nuclear facilities and industrial manufacturers. This guide explains how dosimetry works, why compliance matters, and how to design a cost-effective program that keeps your team safe while meeting US Nuclear Regulatory Commission (NRC), state, and industry requirements.

You’ll also learn the differences between TLD vs. OSL dosimeters, how the ALARA principle applies across industries, and practical tips for building and maintaining a compliant program. Along the way, we’ll highlight real-world case studies, expert guidance, and exclusive RDC advantages such as automatic tiered discounts and same-price options across badge types.

Dosimetry (also known as radiation dosimetry) is the accurate and systematic measurement, calculation, and assessment of the ionizing radiation dose absorbed by matter or tissue. Ionizing radiation includes X-ray, beta, gamma and neutron radiation – energetic electromagnetic waves or particles capable of ionizing the substances they pass through.

When we talk about "emitted radiation," we're referring to the energy released from atoms as they transition from an unstable (radioactive) state to a more stable one. This energy is sent out in the form of particles or electromagnetic waves. A common example of manmade radiation includes radiation-emitting devices, such as X-ray machines.

While you may encounter the Roentgen as a traditional unit for measuring how much X-ray or gamma radiation is present in the air, this measure doesn’t provide information about the effects of that radiation on living tissues. That’s where dosimetry steps in – it goes beyond just exposure, focusing on understanding the actual energy deposited within our bodies.

In this case, we are talking about the energy deposited from the radiation in human tissue.

| Radiation Type | Penetration Ability | Health Risks | Common Sources | Shielding Required |

|---|---|---|---|---|

| Alpha (α) | Very low (stopped by paper or skin) | Harmless externally; dangerous if inhaled, ingested, or enters wounds (can damage tissues/organs) | Radon gas, uranium, radium | Sheet of paper, outer skin |

| Beta (β) | Moderate (can penetrate skin but not deep tissue; stopped by plastic or glass) | Skin burns, tissue damage; more severe if inhaled or ingested, lens of the eye | Medical isotopes (e.g., strontium, phosphorus), industrial tracers | Plastic, glass |

| Gamma (γ) | Very high (penetrates deeply through body and most materials) | Passes through whole body exposure; damages internal organs, tissues, and DNA; increases cancer risk | Nuclear decay, radiotherapy, cosmic sources, particle accelerators | Lead, thick concrete |

| X-rays | High (less than gamma but still strong penetration) | Cellular and tissue damage with prolonged/repeated exposure | Medical and dental imaging, industrial inspection | Lead aprons, concrete, dense barriers |

Gamma rays are an energetic form of electromagnetic radiation, much like X-rays, but with distinct differences that set them apart.

Where do gamma rays come from? Unlike X-rays, which are generated from interactions in the electron shells of atoms, gamma rays originate directly from an atom’s nucleus, typically during radioactive decay. These rays pack significantly more energy, which gives them remarkable penetrating ability; they can pass through dense materials, including the human body and thick layers of shielding, with surprising ease.

This penetrating power is both a blessing and a concern. Gamma rays are invaluable in fields like cancer therapy, industrial imaging, and sterilization, but their energy also means they can interact with living tissue on a cellular level. Unprotected or accidental exposure can damage DNA and other critical cellular components, increasing the risk of acute radiation sickness or, over time, certain cancers.

Interestingly, gamma rays aren’t limited to man-made sources such as medical equipment and industrial meters. They’re also unleashed naturally from cosmic sources. For example, bursts from solar flares or distant cosmic events can emit gamma radiation, sometimes even disrupting electronics here on Earth, a key challenge for organizations like NASA and researchers who track cosmic weather.

In summary, gamma rays are both powerful tools and significant hazards. Their origins in nuclear processes and unmatched penetrative strength demand that we understand their risks and apply rigorous safety measures whenever they are present.

X-rays are one of the most familiar types of ionizing radiation, particularly known for their pivotal role in medical imaging and diagnostics. As a form of electromagnetic radiation, X-rays can penetrate various materials, including human tissue, making them invaluable in healthcare settings for revealing bones and internal structures.

When you receive an X-ray at your dentist’s office or during a medical checkup, the X-ray beams pass through your body and are captured on film or digital sensors, unless shielded by protective gear like lead aprons. This property – passing through soft tissue but being absorbed by denser substances like bone – is exactly what makes them so useful for diagnostic purposes.

However, exposure to X-rays isn’t limited to the doctor’s office. There are also natural sources. For example, the sun and other cosmic phenomena emit X-rays, but our atmosphere does an excellent job of shielding us. People who spend a great deal of time at higher altitudes, such as frequent flyers or airline crew, receive a bit more exposure, though it remains a small fraction compared to occupational limits.

As beneficial as X-rays are, it’s important to remember that, like all forms of ionizing radiation, they can pose risks at higher exposures. Prolonged or repeated exposure without proper precautions can potentially cause cellular damage, which is why strict safety protocols (especially in medical or industrial environments) are always followed. For most people, occasional medical X-rays pose extremely low risks, but minimizing unnecessary exposure remains a cornerstone of best practices in radiation safety.

Alpha radiation, comprised of alpha particles (often symbolized as α), originates from certain naturally occurring radioactive elements such as radium, radon, and uranium. These particles are relatively heavy and carry a positive charge, making them energetic but also quite limited in their ability to travel or penetrate materials.

In fact, something as thin as a single sheet of paper, or even the outer layer of our skin, is sufficient to stop alpha particles in their tracks. This means external exposure to alpha radiation usually isn’t cause for concern.

However, the real issue arises if an alpha-emitting substance enters the body. This can happen if radioactive dust or gas is inhaled, swallowed, or enters through a cut or abrasion. Inside the body, alpha particles can cause significant damage to living tissues and cells due to their high ionizing power concentrated over a very short range.

A real-world example includes radon gas, a common alpha emitter, which can seep into homes from soil, rock, or groundwater. Prolonged exposure to radon, especially in enclosed spaces, is a known health risk and one of the reasons indoor radon testing has become routine in many regions.

Dosimetry includes internal absorptions (ingested, injected, absorbed, or inhaled radioactive substances) and external radiation doses from sources outside the body. These sources can include cosmic radiation, natural radioactive material (which could be found in building materials and soil onsite), and occupational or medical sources of radiation outside the body.

Humans can be exposed to radiation in two broad ways: internally and externally.

Internal radiation exposure can occur through several pathways:

External radiation exposure happens when all or part of the body is exposed to penetrating radiation from an outside source. This may come from:

Internal dosimetry assessment relies on various monitoring, bioassay, and/or radiation detector counting techniques. External dosimetry is based on measurements with a dosimeter or inferred from measurements made by other radiological instruments.

Internal dosimetry comes into play when radioactive material is taken into the body, whether through inhalation, ingestion, absorption, or entry via wounds or medical procedures. In these situations, specialists must determine the committed effective dose equivalent (CEDE) to understand the level of exposure over time. This process is crucial for accurately assessing health risks, especially for individuals working in environments where internal contamination is possible, such as medical, research, or nuclear power settings.

External dosimetry is based on measurements with a dosimeter or inferred from measurements made by other radiological protection instruments.

A dosimeter is a device used to measure the absorbed dose of ionizing radiation.

When it comes to monitoring radiation exposure, dosimeters come in a variety of forms, each leveraging different technologies and functional features to suit diverse environments and needs.

Each type offers distinct advantages, ranging from basic dose tracking to sophisticated, real-time monitoring, allowing organizations to tailor their radiation safety programs to their unique operational requirements.

Some professions encounter ionizing radiation far more frequently than others, making monitoring and dosimetry especially important in these fields. Industries where workers are routinely exposed to radiation include:

In each industry, ensuring accurate measurement and compliance with regulatory dose limits is critical for employee well-being and safety standards.

To further ensure safety when working with ionizing radiation, the ALARA principle comes into play. ALARA stands for "As Low As Reasonably Achievable," and it's exactly what it sounds like: a set of best practices designed to keep radiation exposure to a minimum.

There are three core strategies to follow under ALARA:

Radiation workers can significantly reduce their occupational dose by consistently applying these principles. And of course, wearing a dosimeter further ensures that exposures stay within recommended safety limits by providing an ongoing record of the dose received.

ALARA is not just a theory – it’s a guiding principle that can be applied differently depending on your industry:

Worried about radiation safety? Download our Radiation Compliance Cheat Sheet to quickly identify and address gaps that can put your organization and employees at risk.

Neutron radiation stands out as a particularly potent form of ionizing radiation, distinguished by its ability to penetrate deeply into most materials, including human tissue, more effectively than many other types of radiation. Unlike alpha or beta particles, neutrons don’t carry an electric charge, which means they can travel through dense substances, and shielding is often more challenging.

A distinctive aspect of neutron radiation is its potential to make other materials radioactive through a process called “neutron activation.” This transforms stable substances into radioactive ones, presenting additional ongoing risks even after the initial exposure.

You’ll most commonly encounter neutron radiation in environments like nuclear reactors or during certain particle accelerator operations. Thankfully, rigorous shielding (often layers of water, concrete, or specialized plastics) minimizes exposure in controlled settings. Perhaps the most dramatic example of neutron radiation occurs during the detonation of nuclear weapons.

Exposure to neutron radiation can cause significant biological harm if not carefully managed, underscoring the importance of regular monitoring and robust protection measures for anyone working in or around affected environments.

Beta radiation, made up of energetic beta particles (β), is stronger and more able to penetrate materials than alpha radiation. Unlike alpha particles, beta particles can pass through the outer layer of human skin. While this means they can cause skin injuries such as burns, they typically won't reach internal organs unless inhaled or swallowed.

Standard safety practices include the use of:

These precautions significantly reduce exposure risk during occupational or medical use of beta-emitting sources.

Several isotopes, including those of carbon, strontium, and phosphorus, emit beta radiation. In healthcare, beta radiation plays a role in specific cancer therapies. In other settings, beta radiation is used for precision, such as testing the thickness of materials like paper (think about the quality control processes at a paper mill).

Remember: just like alpha radiation, beta particles pose the most significant risk if beta-emitting materials are ingested or inhaled. Proper handling, personal protective equipment, and monitoring are essential for anyone working with beta-emitters.

Radiation Detection Company is dedicated to keeping you and all your employees safe. We have over 75 years of experience providing quality dosimetry service to over 40,000 companies nationwide.

RDC offers a wide range of affordable and comprehensive radiation badge services to accommodate the needs of any organization, big or small. We also recognize that choosing a solution can be intimidating. If you need help understanding your dosimetry needs, please contact our world-class customer service team. They will be happy to provide guidance.

Below, we've included a basic comparison between the two most common dosimeter types: OSL and TLD. For a more in-depth breakdown, check out the Ultimate Radiation Badge Guide: Everything You Need to Know About Dosimetry Badges.

| Feature | TLD (Thermoluminescent Dosimeter) | OSL (Optically Stimulated Luminescence) |

|---|---|---|

| Detection Physics | Stores energy in crystal lattice; released as light when heated | Stores energy in crystal lattice; released as light when stimulated with laser/LED |

| Sensitivity Range | ~10 mrem (0.10 mSv); LLD ~1 mrem | ~10 mrem (0.10 mSv); LLD ~1 mrem |

| Re-read Capability | Single read only | Can be re-analyzed multiple times |

| Price at RDC | Same price as OSL – with built-in tiered discounts: every 10 badges ordered = automatic volume discount | Same price as TLD – tiered discounts automatically applied |

Our standard OSL badge (or Type 84 badge for photon monitoring) is a 2-element beryllium oxide (BeO) badge with a minimum reportable dose of 10 mrem (0.10 mSv), and a LLD of 1 mrem. These badges are used to monitor occupational exposure to a single individual working with photon radiation and radiation-emitting devices to ensure the dose received remains within the allowable dose limits. The BeO OSL dosimeter is optimal for medical practitioners and technologists, including veterinarians, dentists, chiropractors, employees working in mammography and fluoroscopy, or any practice with potential exposure to photons.

In reference to external radiation exposures, “whole body” is considered to be the head, torso, arms above the elbow, or legs above the knee.

The TLD-XBG is a four-element radiation badge with a minimal reportable dose of 10 mrem (0.10 mSv) and a lower limit of detection of 1 mrem (0.010 mSv). These badges are used to monitor occupational exposure to a single individual working with photon radiation and radiation-emitting devices to ensure the dose received remains within the allowable dose limits.

Our XTLD-XBG extremity is a single-element ring dosimeter for extremities. The ring badge is optimal for radiation workers whose job functions potentially require their fingers, hands, arms, toes, feet, or legs likely to receive radiation exposure above established monitoring requirements. The XTLD-XBG is a one-element radiation detector with a minimal reportable dose of 10 mrem (0.10 mSv) and a lower limit of detection of 5 mrem (0.05 mSv). These employees may benefit from a ring badge to ensure the extremity dose received remains within the allowable dose limit.

Fetal monitors are available for radiation workers who are pregnant to ensure that the fetus does not exceed a significant radiation dose of 500 mrem for the entire gestational period or 50 mrem per month. The badge should be worn on the abdomen to provide the best estimate of the dose to the embryo/fetus.

Area monitors can be used to ensure that the public is not being exposed to more than 100 mrem/year from outside a room/building where radiation is being produced. In addition, they can monitor occupational dose to employees in a room where the source is located or a room near a source that radiation could potentially reach.

The US Nuclear Regulatory Commission (NRC) has established dose limits for occupational exposure for people working with radioactive materials or ionizing radiation (such as X-ray imaging equipment) and external beam radiation therapy. The dose limit functions as a form of radiation protection for personnel monitoring. Radiation dose is often reported in rads, and the dose equivalent is recorded in rems. If you or your staff are working with such materials or equipment, these regulations apply and must be followed.

There are several ways to measure absorbed doses from ionizing radiation. People in contact with radioactive substances in the course of their employment – or people who may be exposed to radiation – normally carry personal dosimeters. These dosimeters are specifically designed to record and indicate the radiation dose received.

Personal dosimetry works by constantly tracking radiation exposure to determine how much radiation an individual has accumulated over time. By wearing a dosimeter throughout their workday, personnel can ensure that their exposure stays within regulatory limits, providing an ongoing record for both safety and compliance.

Today, the film badges of the past have been largely replaced by devices such as the TLD badge, which uses thermoluminescent dosimetry. This shift in technology allows for more accurate, reliable, and sensitive monitoring, ensuring that radiation workers are better protected and that exposures can be promptly addressed if they approach regulatory thresholds.

The measure of the radiation energy deposited in matter by ionizing radiation per unit mass. Absorbed dose is a measurable quantity and a key component of radiation protection as well as radiology.

A crucial piece of radiological protection, effective dose is a calculation that sums up all of the different exposures into a single measure that generally reflects the overall risk for the whole body.

The sum of the products of the dose equivalent to the organ or tissue (HT) and the weighting factors (WT) applicable to each of the body organs or tissues that are irradiated (HE = ΣWTHT).

A measure of the biological damage to living tissue as a result of radiation exposure. Also known as the "biological dose," the dose equivalent is calculated as the product of absorbed dose in tissue multiplied by a quality factor and then sometimes multiplied by other necessary modifying factors at the location of interest.

In practical terms, assessing dose equivalent involves determining how different types of ionizing radiation impact the body. The process begins with identifying the type of radiation a person has been exposed to and assigning a quality factor (Q) specific to that radiation. This quality factor accounts for the varying biological effectiveness of different radiation types, such as alpha, beta, gamma, or neutron radiation.

Here is a slightly more precise way of defining dose equivalent: Dose equivalent is a measure of the biological effect of ionizing radiation on living tissue. It is calculated as the product of the absorbed dose (D) in tissue and a quality factor (Q) that accounts for the type and energy of the radiation, as well as any additional modifying factors at the point of interest:

H = D × Q × N

Where N represents other applicable modifying factors when necessary.

Dose equivalent is sometimes referred to as the biological dose and provides a way to compare the potential biological harm caused by different types of radiation.

By multiplying the absorbed dose (measured in grays or RADs) by the quality factor, we arrive at the dose equivalent, which is expressed in units of rem (Roentgen Equivalent in Man) or sievert (Sv). This value reflects the potential biological risk or effectiveness of the radiation exposure, providing a more meaningful measure for evaluating possible health effects compared to absorbed dose alone.

Background radiation is a measure of the level of ionizing radiation present in the environment at a particular site. This occurs naturally and is not due to the deliberate introduction of a radiation source.

A control dosimeter is a badge that is fundamentally the same as the radiation badge used to protect radiation workers. However, control dosimeters are used to measure external radiation exposure from non-occupational radiation sources. (while the badge worn everyday measures occupational exposure and background radiation). Subtracting from the dosimeter worn by the worker yields the occupational dose.

A control dosimeter is identical in design to the personal dosimeter (or radiation badge) worn by radiation workers, but it is not worn while working. Instead, it is stored in a designated background area, away from occupational radiation sources, to measure background and non-occupational radiation exposure. By subtracting the control dosimeter reading from the worker’s dosimeter reading, the occupational dose can be accurately determined.

Occupational dose is the amount of ionizing radiation exposure received by workers in the course of their employment. A control dosimeter measures the background radiation dose received during shipment (either to you or back to us) and storage. To obtain occupational dose, the measurement recorded on the control dosimeter is subtracted from the individual doses recorded on each badge in the group.

Maintaining a compliant dosimetry program is crucial for all businesses that use radiation in their operations. A dosimetry program helps ensure that levels of occupational dose are kept within safe limits. This, in turn, helps to protect your employees from the potential health risks associated with radiation exposure.

It's extremely important that your dosimetry program is reliable and accurate. Your employees need to understand its function and they are properly trained. Businesses that don’t comply with dosimetry requirements face a number of implications that can negatively impact the success of the company and regulatory compliance.

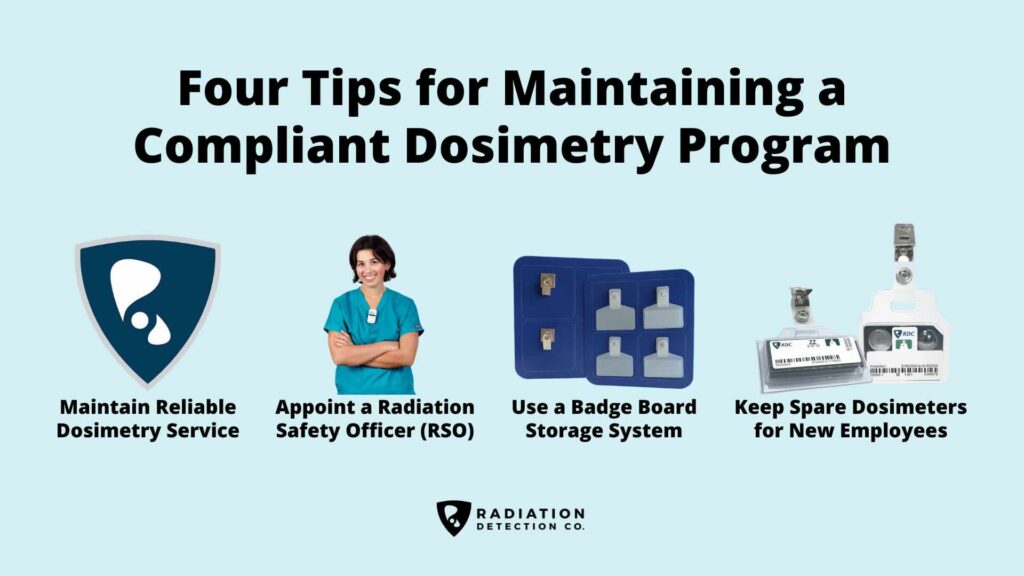

Below, we're sharing four tips to maintain a compliant dosimetry program.

When looking for a dosimetry provider, it's important to find one that can offer you a reliable exchange program. This way, you can be sure that you will always have the badges you need and they'll be properly calibrated. Things to look for when choosing a provider:

By maintaining an active quality assurance program, dosimetry providers should be able to meet basic customer requirements, such as on-time shipping. Delays caused by supply chain issues or operational inefficiencies from the provider can mean you, as the customer, are not able to meet requirements.

On-time performance is a key indicator of a dosimetry provider’s overall reliability and operational maturity. To consistently meet customer requirements (including accurate and punctual shipments), providers must maintain a robust quality assurance program, adequately trained staff, sufficient material and logistical resources, and a resilient supply chain. Breakdowns in any of these areas, whether due to poor planning, limited resources, or supplier delays, can result in missed delivery schedules. Such lapses may prevent customers from meeting regulatory, contractual, or safety obligations, ultimately undermining confidence in the provider’s performance.

A dosimetry service is ultimately designed to produce a final product: the dose report. If the dosimetry provider is unable to produce a dose report in a timely manner, that means that you, as the customer, don't have visibility into the effectiveness of your dosimetry program.

There is nothing more frustrating than not being able to reach a service agent when you need them most. By testing the company's customer service capabilities, you can ensure that you're not stuck fending for yourself.

Reliable and accessible customer support is essential to maintaining a compliant and efficient dosimetry program. Few things are more frustrating or more disruptive than being unable to reach a service representative when urgent adjustments are needed. By evaluating a company’s customer service responsiveness before committing, you can ensure that your team receives timely assistance and avoids unnecessary interruptions in radiation monitoring or reporting.

In addition to responsive customer support, a strong provider should also offer self-service capabilities that allow clients to manage their programs directly when preferred. Features like online account access, badge changes, or reporting tools empower users to make updates efficiently, helping maintain continuity and flexibility without always depending on direct agent support.

Appointing a Radiation Safety Officer (RSO) and/or dosimetry coordinator is a great way to ensure that your dosimetry program is up to date and compliant with all applicable regulations. The RSO can be responsible for maintaining the dosimetry program, training employees in radiation procedures, and ensuring that all equipment is properly maintained and calibrated.

Radiation safety is a vital part of any workplace. By ensuring that your dosimetry program is compliant with all applicable regulations, you can avoid costly fines. You can protect your employees from the potential health risks associated with ionizing radiation.

By using a radiation badge board to help store and organize badges daily, you can save money and reduce the headache of a lost body badge. It costs less than you're currently spending on missing badge fees and helps you maintain a better program. Having a plan in action can help eliminate extra work and stress. It also prevents lost productivity if employees forget their dosimeters at home.

The badge board can be placed away from any radioactive source to neatly keep your badges in order. A swift glance and you can see if anything is missing. This is a quick and easy way to ensure all badges are accounted for at the end of each day.

Here are some additional helpful tips we've gathered from RDC customers to help maintain a good radiation badge program:

Keep a "spare" dosimeter on hand for new hires. This will save you from having to pay rush fees when someone is hired and needs their badge right away. New employees can be given the spare until their own arrives in the mail. You'll end up spending less in the cost of a badge than you would pay for expedited shipping. Plus, you won't waste any payroll dollars by having employees unable to perform key job functions due to a lack of appropriate equipment.

Want to learn more about RDC’s dosimetry badge solutions? Please visit our Solutions page to view our full suite of offerings. Have a question that we did not address in this article? Please reach out to our Customer Care team, and one of our specialists will be happy to assist you.

Dosimetry is the science and practice of measuring, monitoring, and assessing exposure to ionizing radiation. It involves the use of specialized devices – including thermoluminescent dosimeters (TLDs), optically stimulated luminescence (OSL), and digital dosimeters – to track the dose received by individuals or in the environment. The data collected helps protect workers, verify that exposures remain within regulatory limits, and ensure compliance with radiation safety standards.

Radiation safety programs should take preventative measures to reduce exposure risks through ALARA practices, personal dosimetry, and area monitoring.

ALARA is a guiding radiation safety principle that stands for "As Low As Reasonably Achievable." Organizations that work with radiation-emitting equipment and radioactive materials can use time, distance, and shielding techniques to reduce the amount of occupational exposure.

ALARA is a core radiation safety standard designed to minimize occupational exposure, and stands for "As Low As Reasonably Achievable." ALARA is a guiding radiation safety principle that applies to all organizations working with radioactive materials or radiation-emitting equipment.

Here's how organizations that work with radiation-emitting equipment and radioactive materials can use time, distance, and shielding techniques to reduce occupational radiation exposure:

Consistently applying ALARA ensures exposures remain well below regulatory limits while reinforcing a strong safety culture.

The first steps to maintaining a compliant dosimetry program begin with building a strong foundation of reliability, organization, and accountability.

A compliant dosimetry program is not just about meeting regulations – it’s about creating a culture of accountability and protecting the people who make your work possible.

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.