Dosimeter badge services for medical, dental, and veterinary businesses

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.

Senior Vice President of Operations & Technical Services

Last Updated: November 24, 2025

This guide explains the differences between thermoluminescent dosimeters (TLDs), optically stimulated luminescence dosimeters (OSLs), and semi-passive solutions like NetDose™, helping organizations determine which radiation dosimeter best fits their safety program. Learn how each dosimeter works, where it performs best, how to meet NRC and state compliance requirements, and what factors most influence program cost, staff confidence, and reporting efficiency.

Radiation safety is more than a regulatory requirement: it’s a cornerstone of protecting healthcare workers, veterinarians, dental professionals, researchers, and industrial technicians who work with ionizing radiation every day. For organizations across these fields, choosing the right radiation dosimeter is a critical decision that directly impacts staff safety, compliance, and operational efficiency.

But with multiple technologies available, from thermoluminescent dosimeters (TLDs) to optically stimulated luminescence dosimeters (OSLs), and semi-passive solutions like NetDose™ that provide on-demand digital reporting, the question becomes: which one is right for your team?

This comprehensive guide consolidates the latest insights and decades of expertise to help you evaluate dosimeter types, compare their strengths and limitations, and make an informed decision. Whether you’re overseeing a hospital radiology department, a rural dental practice, or a nuclear component manufacturing facility, this article provides the clarity you need.

At its core, a radiation dosimeter (or badge) is a device worn by workers to measure ionizing radiation exposure over time. The results provide a legal dose of record, which regulatory agencies require to demonstrate compliance with occupational safety standards.

Learn more about dosimetry badges – Ultimate Radiation Badge Guide: Everything You Need to Know About Dosimetry Badges

Radiation dosimeters can be grouped into three categories.

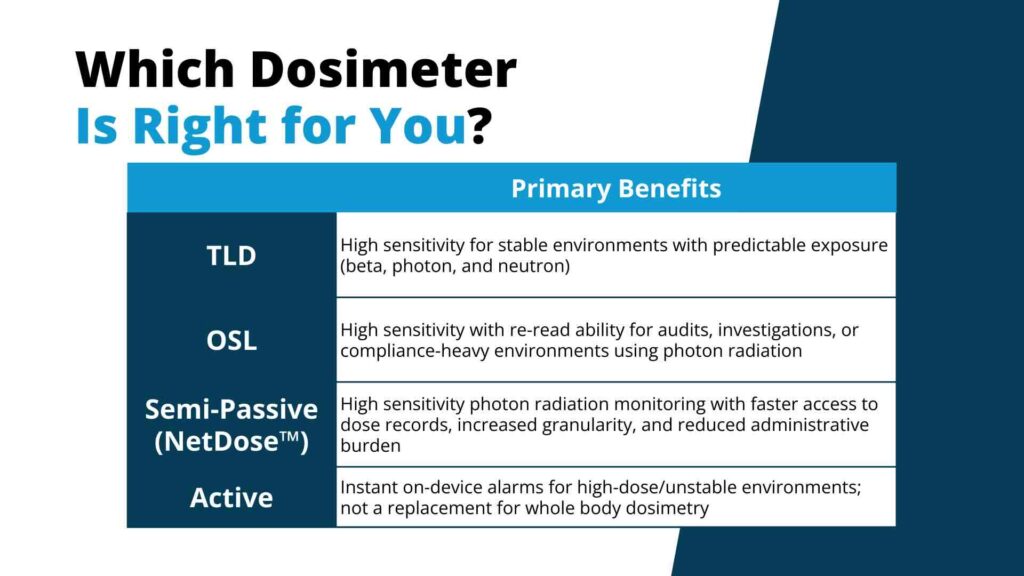

Here’s a high-level comparison of the four main technologies:

| Dosimeter Type | How It Works | Health Risks | Advantages | Limitations |

|---|---|---|---|---|

| TLD | Crystal stores radiation energy, released as light when heated in a lab | Proven, cost-effective, reliable | Durable, widely used, inexpensive | One-time readout, delayed results, limited reuse |

| OSL | Laser light releases stored energy, re-readable multiple times | High sensitivity, durable, re-readable | More sensitive and more re-readable than TLDs | Requires laboratory processing |

| Semi-Passive (NetDose™ Digital Dosimeter) | Bluetooth-enabled dosimeter with on-demand insights (down to hourly) | Faster reporting, compliance-ready, reduced admin burden, scalable | Near real-time data, cloud-based reporting, reduces manual processes | Requires Bluetooth syncing via an app |

| Active Dosimeters | Electronic sensors provide instant alarms and on-device readouts | Real-time alarms, essential in nuclear applications | Immediate feedback, situational awareness | Higher cost, often unnecessary for most industries; not a valid replacement for passive dosimetry |

TLDs contain crystalline material (commonly lithium fluoride). When exposed to radiation, electrons within the crystal become “trapped” in higher energy states. Later, in a lab, the dosimeter is heated, releasing the trapped energy as visible light. The intensity of this luminescence is proportional to the radiation dose.

At Radiation Detection Company, we’ve chosen LiF:Mg,Cu,P as the detector material in our TLD dosimeters because it’s close to tissue equivalent.

TLDs are an excellent choice for nuclear power plants, research universities, and medical centers where the radiation work permit includes monitoring for beta, photon, and neutron radiation.

OSLs use a similar principle to TLDs but release release energy when stimulated with a laser or light emitting diode (LED) instead of heat. This process is non-destructive, allowing the dosimeter badge to be reread multiple times for verification or audits.

At Radiation Detection Company, we use beryllium oxide (BeO) as the detector material in our OSL dosimeters because it’s the most tissue-equivalent material.

OSLs are the gold standard for facilities prioritizing accuracy, durability, and verification capability. They are ideal for organizations relying on photon radiation only – whether in a healthcare, dental, veterinary, research, or industrial environment – where audits and dose verification are routine.

For simplicity’s sake, we’ll use NetDose™ as our semi-passive dosimeter example. Unlike traditional passive dosimeter badges that require a full cycle of lab processing, NetDose™ provides digital reporting in near real time. Data can be delivered on demand, with results available down to the hour through secure digital platforms.

Radiation safety becomes even more personal when it involves declared pregnant employees. Traditionally, staff in this category have had to wait weeks or months for TLD or OSL results to be processed, creating unnecessary anxiety and limiting the ability to make timely adjustments to work practices.

NetDose™ addresses fetal monitoring gaps by providing on-demand, down-to-hourly dose reports. This gives pregnant employees (and their supervisors) peace of mind, ensuring they can track exposure more closely and maintain confidence in their safety throughout the pregnancy.

Semi-passive dosimeters like NetDose™ are best suited for organizations that require photon monitoring (X-ray, gamma) and want fast, regulator-approved reporting and a reduced administrative burden, without the complexity of active alarms. NetDose™ is ideal for pregnant employees who would benefit from on-demand reporting for greater insight and more peace of mind.

Active dosimeters use electronic radiation detectors (typically Geiger-Müller tubes, silicon diodes, or ionization chambers) to measure exposure in real time during the wear period. Unlike passive or semi-passive badges that require processing or syncing to generate reports, active dosimeters provide instantaneous readings directly to the wearer.

However, active dosimeters are not NVLAP-accredited and cannot serve as the legal dose of record. Instead, they function as supplemental safety tools for environments where immediate awareness of exposure is critical. In some environments, active dosimeters may be required alongside a NVLAP-approved passive dosimeter, which provide the legal dose of record.

Most active dosimeters are equipped with:

Active dosimeters are used primarily in high-risk radiation environments where instantaneous feedback can prevent acute overexposure. They are most appropriate for:

In these settings, the ability to alarm in real time helps protect personnel from unexpected dose spikes.

Active dosimeters are typically overkill for most healthcare, dental, veterinary, and industrial users, but necessary for high-risk nuclear applications. They do not provide a legal dose of record and only act as a complement to NVLAP-approved dosimeters.

For radiation safety officers (RSOs) and compliance leaders, the decision often comes down to sensitivity, verification, reporting speed, and administrative efficiency. Here’s how the main dosimetry technologies compare:

| Feature | TLD | OSL | NetDose™ (Semi-Passive) | Active Dosimeter |

|---|---|---|---|---|

| Radiation Measured | X-ray, Beta, Gamma, Neutron | Gamma and X-ray | Gamma and X-ray | Varies by model |

| Minimum Reportable Dose | 10 mrem (0.1 mSv); down to 1 mrem by client request | 10 mrem (0.1 mSv) | 1 mrem (0.01 mSv) per month | Varies by model; typically sub-mrem |

| Lower Limit of Detection | 1 mrem (0.01 mSv) | 1 mrem (.01 mSv) | 1 mrem (0.01 mSv) per month | Varies by model |

| Accreditation | NVLAP (Lab Code: 100512-0) | NVLAP (Lab Code: 100512-0) | ANSI N13.11; IEC 62387; NVLAP 600295-0 | Not NVLAP-Accredited |

| Fade | <4% | <4% | N/A | N/A |

| Usability | Worn for a specific, client-defined wear period | Re-readable | Continuous use (Battery up to 3 years) | Continuous use (Battery 1 month–5 years) |

| Environmental Durability | Moderate | High | High | High |

| Stimulation Method | Heat (destructive) | Light (non-destructive) | N/A (Bluetooth + digital readout) | Instant electronic readout |

| Exchange Cycle | Required | Required | Not required | Not required |

| Reporting Speed | End of wear period | End of wear period | On-demand, down to hourly | Immediate |

| Reporting Periods | Monthly, Bi-Monthly, Quarterly, etc. | Monthly, Bi-Monthly, Quarterly, etc. | On-demand | Real-time only; not dose-of-record |

| Dose Report Delivery Method | Uploaded to client portal | Uploaded to client portal | Digital delivery + dashboards | Device + software (not dose-of-record) |

| Best Use Case | Cost-sensitive, stable programs | Audit-driven, compliance-heavy programs | High-risk, healthcare, industrial, declared pregnancy | Nuclear power, radiation emergencies |

To simply things, here's a summarized interpretation of the table above:

Ultimately, every organization is responsible for choosing the dosimetry solution that meets the regulatory requirements for their industry. Below is a generalized summary of the most common regulatory agencies that oversee radiation monitoring.

From a dosimetry perspective, the NRC sets the federal requirements for radiation protection – defining dose limits, when workers must be monitored, and how exposure records must be kept and reported (e.g., under 10 CFR Part 20). It then licenses and inspects its regulated facilities and materials users, enforcing these requirements and ensuring worker and public doses remain within regulatory limits.

The NRC accepts NVLAP-accredited TLD, OSL, and semi-passive systems such as NetDose™ as the legal dose of record (RDC NVLAP Lab Code 100512-0, NetDose™ NVLAP Lab Code 600295-0). The NRC does not allow active dosimeters to serve as the sole monitoring solution for a legal dose of record.

From a dosimetry perspective, OSHA sets and enforces workplace safety standards for ionizing radiation exposure, which include dose limits, area posting, personal monitoring, training, and record-keeping requirements for employers. OSHA also inspects workplaces, cites violations, and requires corrective actions to ensure employers are monitoring workers appropriately.

OSHA enforces workplace safety standards but defers to the NRC and state-level agencies for radiation exposure requirements.

State regulators set and enforce rules for the use of X-ray machines and radioactive materials, including when and how workers must be monitored with dosimetry and how exposure records are maintained. They inspect facilities for compliance with these requirements, investigate overexposures, and align their programs with federal standards (e.g., NRC) to ensure adequate protection of workers and the public

Some states specify badge exchange intervals (e.g., monthly vs. quarterly), which may influence whether a program selects TLDs, OSLs, or NetDose™.

The Healthcare Joint Commission increasingly emphasizes timely, auditable dose reporting, encouraging hospitals and imaging centers to consider solutions that reduce reporting lag and support proactive oversight. From a dosimetry perspective, The Joint Commission (TJC) doesn’t set dose limits but drives how hospitals manage and monitor patient and staff radiation dose as part of accreditation.

When evaluating dosimetry solutions, cost is understandably a deciding factor – every organization is under pressure to do more with less. Still, it’s important to look beyond the unit price of each dosimeter badge and consider the total program cost, including administrative effort, reporting needs, and compliance requirements.

While we can’t speak to other dosimetry providers, here are some cost considerations in relation to Radiation Detection Company (RDC). For a personalized cost estimate, you can call us at 800.250.3314 or submit a contact form.

Enterprise organizations receive significant high-volume discounts, making RDC highly competitive in the market. While published unit pricing is transparent for small practices, enterprise buyers should know that pricing scales to reflect program complexity, dosimeter badge volume, and long-term partnerships.

Choosing the right dosimeter depends first and foremost on what types of radiation are present in your environment – beta, photons (X-ray, gamma), or neutron – and whether your program needs re-readability, audit support, or faster reporting. Below is practical guidance for each industry based on those factors.

Primary radiation types: Photons (X-ray, gamma). Some departments may involve beta, depending on procedures or isotopes used.

OSL dosimeters are strongly recommended for hospitals and healthcare environments because they can be re-read and archived, supporting incident investigations, audit requirements, and regulatory documentation. Re-readability is independent of hospital size – it is a best practice for all healthcare programs where verification matters.

Appropriate when beta radiation is present, or in hybrid environments where multiple radiation types must be monitored. TLDs remain a reliable option but cannot be re-read, which is a limitation for audit-heavy hospital programs.

Highly beneficial in departments that need faster reporting, such as fluoroscopy, cath labs, diagnostic imaging, mobile X-ray, and for declared pregnant employees who benefit from on-demand reassurance.

Not required for typical medical imaging or radiation therapy workflows. Used only when radioactive materials or high-risk isotopes are handled and immediate alarms are necessary. Active dosimeters cannot serve as the legal dose of record.

Primary radiation types: Photons (X-ray).

Both TLD and OSL dosimeters are suitable because clinics historically use photon-only radiation. Choose OSL if your practice prefers the ability to re-read badges or maintain longer-term dose verification.

Useful in specialty veterinary or dental oncology practices that want faster reporting or more frequent exposure insights, but not required for most practices.

Not necessary in these settings.

Primary radiation types: Photon-only, beta + photon, or beta + photon + neutron depending on facility type.

If any beta radiation is present, or if beta, photons, and neutron exposure must be monitored together, TLDs are the appropriate choice. TLD materials handle these energy types reliably and maintain accuracy across varied conditions.

Ideal for photon-only industrial environments requiring precise dose tracking and the ability to re-read badges (e.g., nondestructive testing, industrial X-ray operations).

Valuable in industrial programs needing enhanced operational oversight or near real-time exposure insights – such as aerospace manufacturing, electronics inspection, or nuclear component production – where streamlined compliance workflows reduce risk.

Reserved for nuclear power plants, isotope production facilities, or environments with significantly high-energy fields where real-time alarms are essential. Active dosimeters remain a supplement, never the official dose of record.

Each dosimetry technology has its place; the right choice depends on your program’s risk profile, compliance requirements, and administrative needs.

Here’s some general guidance to help you choose the right solution for your time. If you need more support, contact the dosimetry experts at Radiation Detection Company.

For most organizations, passive dosimetry (TLDs and OSLs) is the right foundation. Semi-passive solutions like NetDose™ enhance programs where speed and efficiency add value, while active dosimeters remain necessary only in highly specialized environments.

Looking for more information? Check out this blog – Complete Dosimetry Program Management Guide: Setup, Compliance & Cost Optimization

Radiation dosimetry has evolved to offer organizations more flexibility than ever before. Passive dosimeters like TLDs and OSLs remain the foundation of most monitoring programs – delivering reliable, cost-effective, and regulator-approved dose records trusted across healthcare, dental, veterinary, and industrial environments.

For organizations that require faster reporting cycles, digital delivery of records, peace of mind for pregnant employees, or reduced administrative overhead, semi-passive solutions like NetDose™ provide an excellent complement. They bridge the gap between traditional passive dosimetry and true active systems, offering near real-time reporting without unnecessary complexity.

The right choice depends on your facility’s risk profile, compliance requirements, and operational needs. In many cases, TLDs or OSLs are the best fit. In others – especially high-risk environments or programs with complex compliance requirements – a semi-passive solution like NetDose™ may deliver added value.

Either way, Radiation Detection Company is here to help. Complete our contact form now or call 800.250.3314 to speak to take the guesswork out of your dosimetry program. Radiation safety and dosimetry program management is easy when you have the right support in your corner.

Not entirely. While digital adoption is growing, TLDs and OSLs remain widely used due to cost-effectiveness and familiarity.

NVLAP-accredited devices such as RDC’s NetDose™ (Lab Code 600295-0) are approved by the NRC and provide full compliance documentation. NetDose™ provides validated dose records that meet all regulatory requirements and are fully compliant with NRC and state guidelines.

Exchange periods depend on your organization’s needs. Radiation Detection Company offers various exchange periods, including:

Active dosimeters do not require exchange periods because they do not provide a legal dose of record.

Yes. Unlike TLDs, OSLs retain stored dose data even after initial processing.

The short answer is it depends on the type of occupational radiation used. OSL is ideal for photon-only environments that might require re-reads or dose verifications. NetDose™, a semi-passive digital dosimeter, is more ideal for high-risk environments (like cath labs, mobile x-ray units, fluoroscopy, and mammography) or pregnant employees who value on-demand reporting for peace of mind.

Yes, but only in specialized cases such as nuclear facilities or direct radioactive material handling, where instant alarms are essential. It’s important to note that active dosimeters do not provide a legal dose of record, and are meant to supplement (not replace) NRC-approved dosimetry solutions.

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.