Comprehensive Guide to Personal Radiation Detection: Devices, Technology, & Applications

Written by

Mirela Kirr

Senior Vice President of Operations & Technical Services

Last Updated: December 2, 2025

Discover how modern radiation detection devices protect workers, improve safety programs, and ensure compliance – from TLD and OSL dosimeter badges to digital dosimeters.

Modern radiation safety depends on accurate, responsive, and reliable personal detection. From hospitals and laboratories to manufacturing and aerospace facilities, radiation detection devices play a crucial role in protecting workers and maintaining compliance.

This comprehensive guide explores the science and technology behind personal radiation detectors, the key differences between dosimetry approaches, and how to select the right solution for your organization’s environment, compliance needs, and operational scale.

Key Takeaways

- Radiation detection devices identify and measure ionizing radiation exposure to ensure compliance with NRC and state regulations.

- Personal dosimeter badges (TLD, OSL, and digital technologies) record cumulative exposure over time as a legal dose of record.

- Detection technologies vary by radiation type (alpha, beta, gamma, neutron) and operational need (passive, semi-passive, or active).

- A reliable monitoring program supports ALARA compliance and reduces administrative burden.

What Is Personal Radiation Detection?

Personal radiation detection refers to the tools and technologies that measure exposure to ionizing radiation for individuals working near radiation-emitting materials or equipment.

Ionizing radiation has enough energy to knock electrons out of atoms – a process that can alter cell structure and damage DNA. Excessive or unmonitored exposure can increase the risk of long-term health effects such as cancer, making reliable detection and monitoring a core component of occupational safety.

Radiation safety isn’t just a best practice – it’s required by law. The US Nuclear Regulatory Commission (NRC) and state regulators establish strict dose limits for occupational exposure. Reliable radiation detection programs ensure organizations do not exceed these limits while maintaining accurate dose records for every monitored worker.

For a deeper understanding of how dosimetry programs support compliance, visit the Complete Dosimetry Program Management Guide.

How Radiation Detection Devices Work

When ionizing radiation interacts with matter, it produces measurable changes that can be captured by specialized materials or sensors. Detection systems translate these physical effects into quantifiable readings of radiation dose or intensity.

There are a few ways to measure an absorbed dose from ionizing radiation. Those in contact with radiation throughout their employment can carry a personal radiation dosimeter specifically designed to record and indicate the radiation dose received by the dosimeter badge wearer.

Organizations exchange dosimeter badges with their dosimetry service provider at the end of each reporting period. Dosimetry service providers, like Radiation Detection Company (RDC), process each dosimeter badge and provide an occupational dose report for every badge wearer.

The personal dose equivalent (sometimes referred to as occupational dose or dose) is defined as the dose in tissue at an appropriate depth in the human body.

Personal dosimeter badge records provide cumulative dose exposure over a defined period for regulatory documentation, forming the backbone of modern radiation protection programs.

For more on the science behind dosimeter badges, check out the Ultimate Radiation Badge Guide: Everything You Need to Know About Dosimetry Badges.

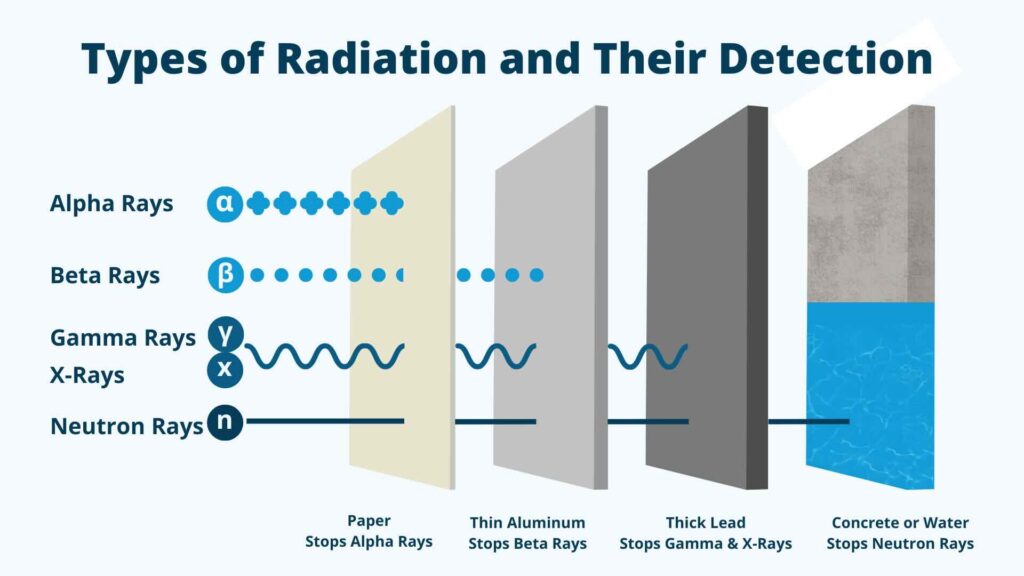

Types of Radiation and Their Detection

Radiation comes in different forms, and each requires specific detection techniques and materials.

Types of Radiation. (Adapted from Radiation; Types of Radiation; 2025; American Nuclear Society, https://www.ans.org/nuclear/radiation/.)

For a full breakdown of radiation particle types and behaviors, read Alpha, Beta, and Gamma Rays: Common Types of Radiation.

Alpha Particles (α)

Alpha radiation consists of two protons and two neutrons, making alpha particles heavy, highly charged, and low in penetration power. These particles can be stopped by a single sheet of paper or the outer layer of human skin, but they pose a significant internal hazard if inhaled, ingested, or absorbed through a wound.

Beta Particles (β)

Beta particles are high-energy electrons or positrons emitted during radioactive decay. They are much lighter than alpha particles and can penetrate further, passing through skin and thin layers of tissue, potentially damaging underlying cells.

Gamma Rays (γ)

Gamma rays are high-energy electromagnetic photons that can travel long distances and penetrate most materials, including human tissue, concrete, and metal. This makes gamma radiation challenging to shield and important to monitor in occupational environments.

Neutron Radiation

Neutrons are uncharged particles released during nuclear reactions or from isotopic sources like californium-252. Because they have no electrical charge, they interact weakly with matter, making neutron radiation difficult to detect and shield against.

The type of radiation used in your occupational environment and industry-specific regulatory requirements will help determine the type of radiation detection device your organization uses.

Types of Personal Radiation Detection Devices

1. Passive Dosimeters

Passive dosimeters like TLD (thermoluminescent) and OSL (optically stimulated luminescence) absorb radiation over a wear period – typically one to three months (based on client risk and detector properties). They’re processed in a laboratory to produce dose reports.

- Examples: TLD dosimeter badge, OSL dosimeter badge

- Advantages: Reliable, affordable, compliant with NRC and state monitoring requirements

- Limitations: Delayed feedback until post-processing

2. Semi-Passive Dosimeters

Semi-passive systems combine the simplicity of traditional dosimeter badges with near real-time data access. These devices store radiation data that can be uploaded to an app or online platform, offering hourly reporting and compliance visibility.

- Example: NetDose™ digital dosimeter

- Advantages: Faster and more granular dose insights, reduced administrative burden, ideal for hospitals or labs managing multiple departments

- Limitations: Slightly higher cost but substantial efficiency gains

3. Active Radiation Detectors

Active dosimeters provide real-time radiation readings with audible and visual alarms, suitable for high-risk or mobile environments.

- Examples: Handheld survey meters, Geiger counters, and electronic personal dosimeters (EPDs)

- Advantages: Immediate feedback; excellent for fieldwork or emergency response

- Limitations: Higher cost, more maintenance, requires the use of a passive dosimeter that constitutes the dose of record

For an in-depth comparison of these dosimeter badge types, see our Guide to Radiation Dosimeter Types: TLD, OSL & Digital Technology Comparison.

Placement of Radiation Dosimeters

Choosing the right type of radiation dosimeter is only part of building an effective monitoring program – proper placement is just as important. Where employees wear their dosimeter badges depends on the nature of their work, how they interact with radiation, and which parts of the body are most likely to be exposed.

Whole Body Dosimeters

Whole body dosimeters are worn on the torso and provide a comprehensive measure of total body exposure. They are essential for workers in environments where radiation exposure is more uniform across the body, such as nuclear facilities, imaging departments, or industrial radiography operations.

Benefits of Whole Body Dosimeters

- Capture overall occupational dose from multiple radiation sources

- Serve as the primary dosimeter badge for most occupational radiation workers

- Support compliance documentation as the legal dose of record for regulatory reporting

Ring Dosimeters

Ring or extremity dosimeters are worn on the finger and are ideal for workers who handle radioactive materials directly. They measure radiation dose to the extremities, providing a localized assessment of exposure to the hands – areas often disproportionately exposed to radiation sources during imaging or nuclear medicine procedures.

Benefits of Ring Dosimeters

- Provide precise dose measurements to the area of highest exposure

- Commonly used in nuclear medicine departments; at RDC, we also recommend ring dosimeters for veterinary practices, as staff may hold animals during X-rays

- Help ensure compliance by documenting extremity exposure separately from whole body dose

Wrist Dosimeters

Similar to ring dosimeters, wrist dosimeters, worn like a watch, are useful for workers whose hands and arms are in the radiation field. These dosimeter badges are available for radiation workers who require flexibility due to dexterity issues or specific safety constraints.

Benefits of Wrist Dosimeters

- Offer a practical alternative to ring dosimeters, particularly in nuclear medicine settings where dose distribution varies across the hand

- Provide targeted monitoring for workers who routinely manipulate radioactive materials or operate fluoroscopy equipment

Fetal Monitoring Dosimeter Badges

Fetal monitoring badges are specialized dosimeters designed for declared pregnant employees who work with or around radiation. These dosimeter badges help ensure the safety of both the pregnant worker and the unborn child by closely tracking exposure throughout the gestational period.

Fetal badges should be worn close to the abdomen, near the location of the embryo/fetus, to obtain the most accurate dose.

Benefits of Fetal Monitoring Badges

- Provide accurate, personalized monitoring to ensure fetal dose limits are not exceeded

- Support compliance with NRC regulations, which limit exposure to 500 mrem for the entire pregnancy and 50 mrem in any single month

- Give declared pregnant workers greater peace of mind and confidence in the safety of their working environment

Factors to Consider When Choosing a Personal Radiation Detector

Selecting the right personal radiation detector goes beyond just meeting regulations. Organizations must take proactive steps to ensure accurate, consistent, and dependable monitoring for every employee who works near ionizing radiation. The following factors can help you determine which radiation dosimeter best suits your environment, personnel, and compliance needs.

Sensitivity

Sensitivity is one of the most important considerations when selecting a radiation dosimeter. Different dosimeter types detect different radiation energies and levels, and not all dosimeter badges are designed to measure every form of exposure. Understanding your workplace’s specific radiation sources (whether X-ray, gamma, or beta) ensures you choose a dosimeter badge that can detect and record the appropriate energy range.

At Radiation Detection Company, we’ve chosen BeO OSL and LiF:Mg,Cu,P TLD. They offer high sensitivity while staying close to tissue equivalence.

Accuracy

Accuracy is critical when protecting occupational radiation workers. A dosimeter’s ability to accurately measure and record dose exposure ensures both worker safety and organizational compliance.

Two important performance factors affect accuracy:

- Thermal Fade: This refers to the loss of signal after exposure. For example, if an employee receives a dose early in the wear period, the dosimeter badge may lose some signal before processing, leading to potential underreporting. The TLD and OSL dosimeters used by RDC have very low thermal fade (typically less than 4%), maintaining reliable results throughout the wear period.

- Lower Limit of Detection (LLD): The LLD determines the smallest measurable radiation dose. An LLD that is appropriate for a one-day dosimeter badge may not be sufficient for quarterly wear cycles, as detection sensitivity is a function of wear duration.

Both TLD, OSL, and semi-passive dosimeters deliver a high degree of accuracy across a wide range of environmental conditions, making them a strong choice for monitoring even minimal exposure levels.

At RDC, our dosimeters offer market-leading lower limit of detection performance.

Compliance Requirements

Radiation monitoring requirements vary by federal and state regulatory agencies. Staying compliant means understanding which dosimeter badge types, wear periods, and dose-reporting methods meet the standards for your specific operation.

Key compliance considerations should include:

- The types of radiation used in your workplace

- The required frequency of dosimeter badge exchanges (monthly, quarterly, etc.) for your industry

- The dosimeter type and calculation methods used for accurate dose reports

- Third-party accreditations and/or regulatory requirements – always partner with a NVLAP-accredited dosimetry provider to ensure your reports fulfill legal dose of record requirements

If you’re unsure which regulations apply to your facility, consult with your Radiation Safety Officer (RSO), review your equipment licensing documents, or contact your state regulatory authority for guidance.

To evaluate your organization’s compliance efficiency, download the Radiation Compliance Cheat Sheet.

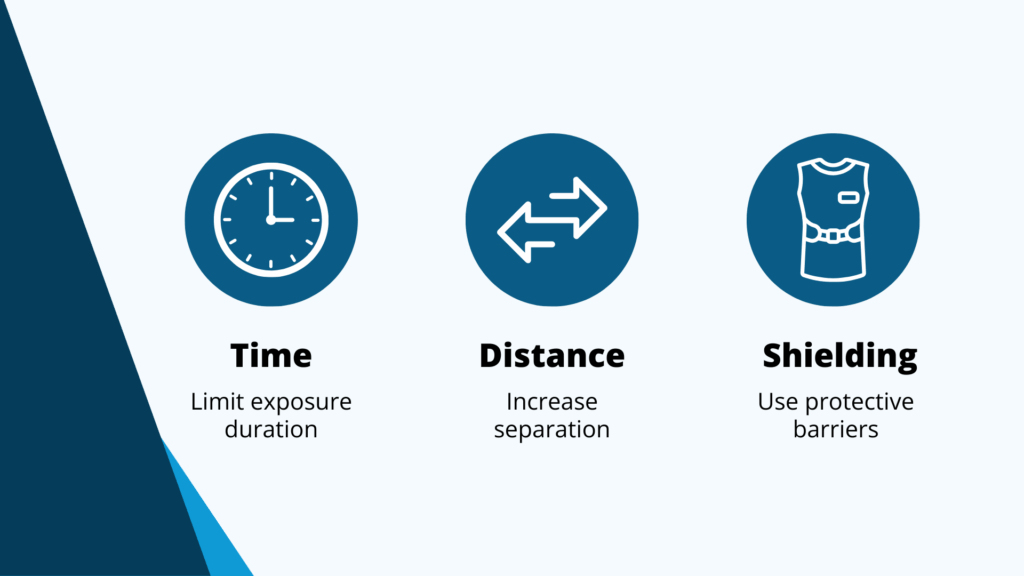

Prioritizing ALARA

The ALARA principle (“As Low As Reasonably Achievable”) is the cornerstone of radiation safety. It guides every monitoring program to minimize occupational and public exposure without hindering essential operations.

ALARA is built on three fundamentals:

- Time: Limit the duration spent near radiation sources. Plan and practice procedures in non-radiation areas to reduce on-site exposure.

- Distance: Maximize space between personnel and sources; even doubling your distance can cut exposure to one-quarter of the original dose.

- Shielding: Use protective barriers like lead aprons, concrete walls, or steel enclosures to block or attenuate radiation.

These principles work together to ensure doses remain well below regulatory limits.

Learn more about effective shielding materials in Your Complete Guide: Materials That Block Radiation.

Use Cases for Radiation Detection Devices

Personal radiation detection is critical across every industry where ionizing radiation is present. Whether used to protect medical staff, calibrate precision manufacturing equipment, or verify nuclear shielding performance, these technologies form the backbone of a compliant, data-driven radiation safety program.

Healthcare

In healthcare settings, dosimeters protect frontline staff in diagnostic imaging, radiology, and nuclear medicine. Whole body dosimeter badges monitor total exposure, extremity rings track localized hand doses, and fetal monitors ensure declared pregnant workers remain under the NRC’s 0.5 rem pregnancy limit. Digital and semi-passive solutions like NetDose™ give Radiation Safety Officers real-time visibility, improving safety and ALARA compliance –especially in interventional radiology, where exposure can vary widely by procedure.

Manufacturing

In manufacturing and industrial environments, including aerospace, automotive, and electronics, X-ray systems are routinely used for non-destructive testing (NDT), weld inspection, and material calibration. OSL and TLD badges provide reliable dose of record documentation, while centralized platforms like MyRadCare™ streamline data tracking across multiple sites. Engineers often pair dosimetry programs with handheld detectors and area monitors to confirm shielding effectiveness and maintain equipment accuracy.

Research Laboratories

In research and laboratory settings, personnel work with sealed and unsealed isotopes, making consistent exposure tracking vital. Passive dosimeter badges ensure regulatory documentation, while semi-passive digital dosimeters provide faster data for high-activity or variable radiation environments.

Nuclear Energy

In nuclear and energy industries, workers are exposed to mixed radiation fields, including gamma radiation, neutron radiation, and beta particles. TLD + Neutron dosimeter badges and proportional counters enable accurate monitoring of complex environments. Semi-passive dosimeters provide real-time visibility and operational transparency for maintenance crews, inspectors, and safety teams.

Traveling Employees

Finally, for traveling employees and field technicians, who often move between hospitals, research facilities, or manufacturing sites, semi-passive digital solutions like NetDose™ simplify dosimeter badge management. Remote uploads ensure compliance visibility and accurate exposure reporting no matter where work occurs.

For detailed guidance on multi-site or mobile workforce monitoring, explore Optimizing Dose Monitoring for Traveling Employees.

Choosing the Right Personal Radiation Detector

Selecting the right solution depends on three key factors:

- Type of Radiation: Match detection materials to alpha, beta, gamma, or neutron sources.

- Operational Environment: Determine whether you need continuous readouts (active) or cumulative reporting to serve as a legal dose of record (passive/semi-passive).

- Data and Compliance Needs: For multi-department facilities, digital systems simplify program management through centralized reporting platforms like MyRadCare™.

Need expert guidance? Contact Radiation Detection Company or call 800.250.3314 for a consultation on program setup and optimization.

Conclusion

Radiation detection technology continues to evolve, bridging the gap between traditional dosimeter badges and intelligent, connected systems that empower safety leaders with real-time visibility. Whether you’re managing a hospital radiation safety program or overseeing exposure control in manufacturing, choosing the right personal radiation detection devices is key to both compliance and worker protection.

To discuss your organization’s monitoring needs or request a consultation, contact Radiation Detection Company or call 800.250.3314.

Frequently Asked Questions

What is the best personal radiation detection device?

The best device depends on your needs. You should choose a dosimeter based on the type of radiation present in the workplace; your dosimeter needs to be appropriate for the radiation work environment based on the radioactive materials license for your workplace equipment. Be sure to use a NVLAP-accredited dosimetry provider and a NVLAP-accredited dosimeter.

How often should I read or exchange my dosimeter badge?

Most organizations follow a monthly or quarterly exchange cycle. Digital systems automate this process, reducing unreturned dosimeter badge fees, missed reads, and reporting delays.

Do radiation detection devices detect all types of radiation?

Not all. Some dosimeter badges are optimized for gamma and X-ray radiation, while neutron detection requires a TLD + Neutron badge.

Can a personal radiation detector replace dosimetry badges?

No. Handheld detectors provide instant readings but do not meet NRC requirements for official dose of record documentation. Personal dosimeter badges are still mandatory for occupational compliance.