Dosimeter badge services for medical, dental, and veterinary businesses

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.

President, Radiation Detection Company

Last Updated: October 23, 2025

Accurate personnel dosimetry isn’t just about detector material, it’s about how you handle depletion. This article explores how BeO and Al₂O₃:C OSL detectors respond under strong-beam stimulation, and why depletion correction defines true dosimetry accuracy in low-dose environments.

In personnel dosimetry, accuracy often comes down to what happens after the badge is read. Most professionals focus on detector materials, whether Al₂O₃:C or BeO, but overlook how optical stimulation and depletion handling impact the reported dose.

Optically stimulated luminescence (OSL) systems read stored radiation energy by stimulating the detector material with light and measuring the resulting luminescence. But the very act of reading the signal can deplete it, reducing the stored information that represents the dose.

If this depletion isn’t properly understood or corrected, the apparent precision of a “confirmation” read may mask a hidden bias. That’s why understanding the depletion characteristics and correction algorithms is fundamental to dosimetry accuracy –especially at low occupational doses.

Every OSL dosimeter stores trapped electrons in defects within its crystal lattice. During readout, a light source (often a laser or LED) stimulates these trapped charges, releasing them as photons. The emitted luminescence is proportional to the absorbed dose.

But here’s the catch: once those electrons are released, they’re gone. The signal cannot be re-read without correction. That’s where depletion handling becomes central to dosimetry accuracy.

Inaccurate depletion handling can lead to:

Therefore, depletion handling isn’t a secondary calibration detail; it’s a core determinant of reliability in modern OSL dosimetry systems.

The Al₂O₃:C detector, used widely in commercial OSL dosimeters, has exceptional sensitivity and a well-characterized luminescent response. However, under photo-stimulated luminescence (POSL) with strong-beam protocols using a YAG laser, it behaves predictably … but not benignly.

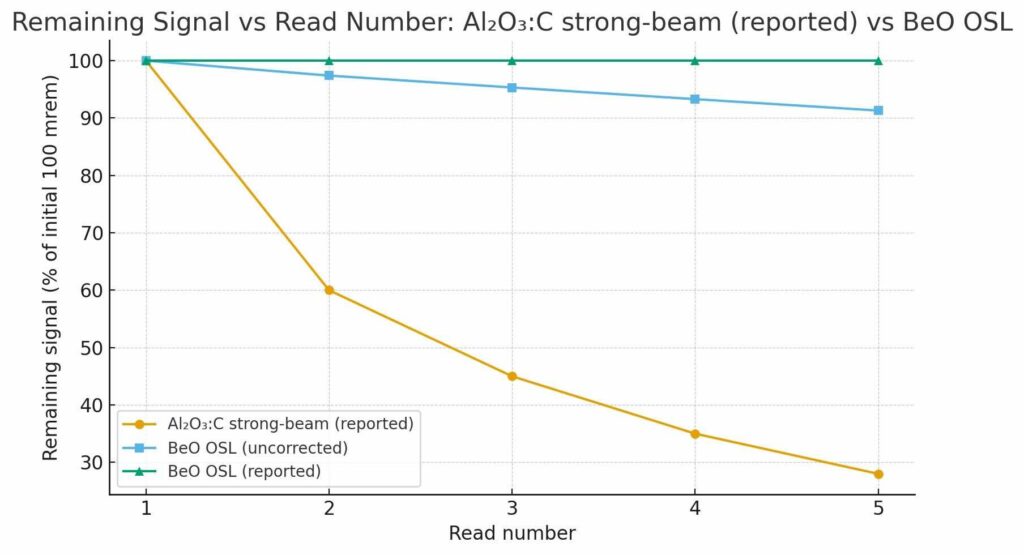

At 100 mrem (1.00 mSv), the depletion pattern for Al₂O₃:C is highly reproducible with about a 3% standard deviation; the issue isn’t stability, it’s loss magnitude. Under a typical strong-beam read sequence:

The chart below illustrates how signal retention drops sharply with each read in Al₂O₃:C systems, compared to minimal depletion observed in BeO OSL systems.

For many monitoring programs, the second read is used as a “confirmation.” Since the depletion ratio is consistent from one dosimeter to another, agreement between the first and second read appears to confirm validity.

However, in reality, this “confirmation” read is not a correction – it merely verifies the expected depletion fraction, not the true dose.

Reproducibility makes Al₂O₃:C strong-beam systems reliable in pattern, but not necessarily accurate in dose restoration without algorithmic correction.

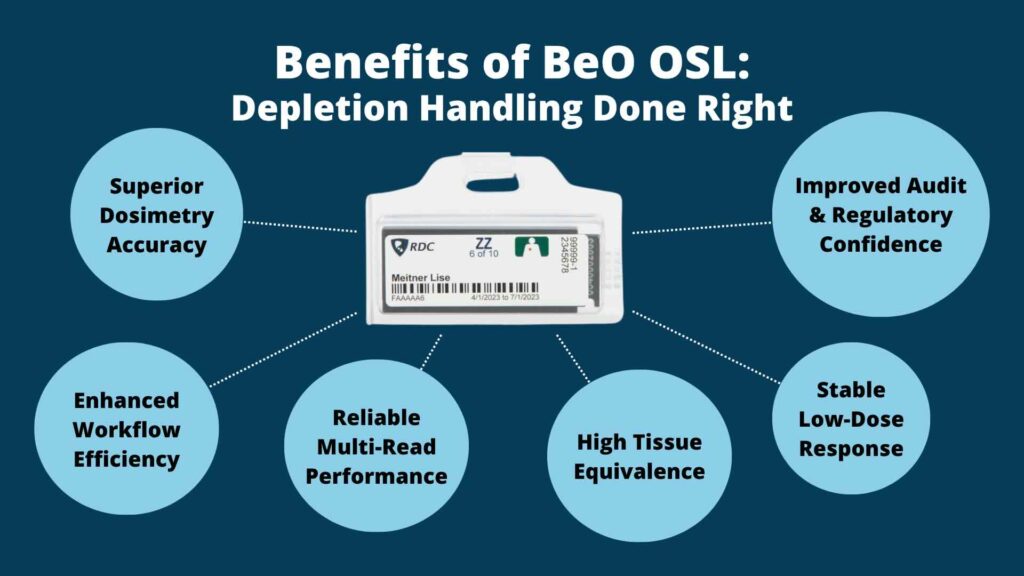

Beryllium oxide (BeO) OSL technology represents a newer generation of dosimetry materials and system design. BeO offers several intrinsic advantages:

A 2025 Journal of Applied Clinical Medical Physics characterization of a commercial BeO OSL platform found:

At a 100 mrem (1.00 mSv) exposure, a second uncorrected read would report roughly 97.4 mrem (0.974 mSv). Subsequent reads drop by only ~2% each, and crucially, these systems apply depletion correction algorithms to restore accuracy automatically.

BeO OSL can perform multiple reads without introducing significant cumulative error, supporting robust dose verification, audit workflows, and cross-system consistency.

Learn more about the advantages of BeO OSL technology – ORA™ OSL Ring: The First Accredited Extremity Dosimeter in the US Market.

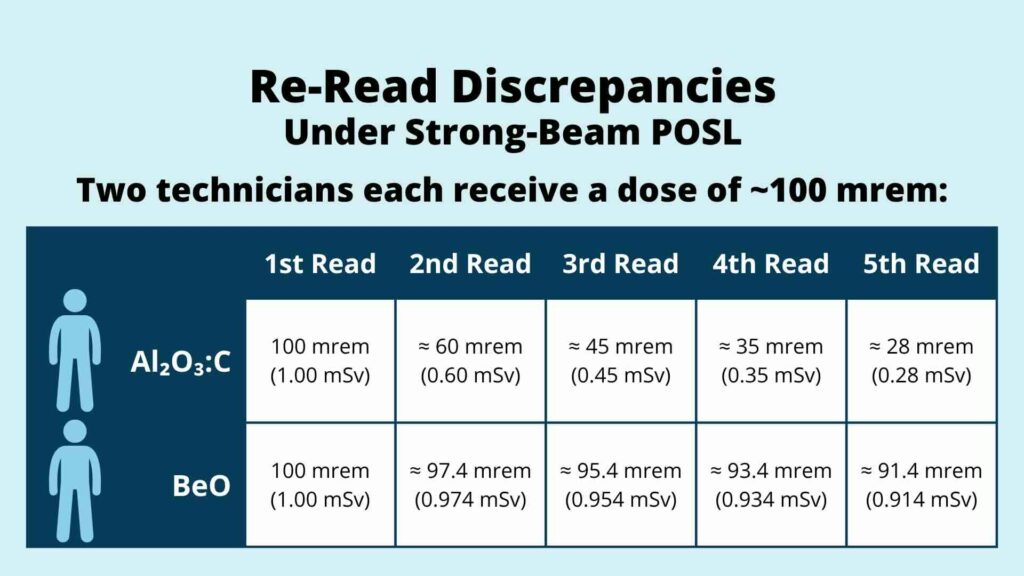

In low-dose regimes (e.g., under 1 mSv), small percentage losses can translate into meaningful discrepancies in occupational monitoring. Consider two technicians each receiving ~100 mrem:

That’s a 30-40% difference arising not from radiation exposure, but from readout methodology.

In radiation safety, that difference could alter cumulative dose tracking, regulatory record accuracy, and audit defensibility. Especially in medical imaging, interventional radiology, and mixed-beam environments, where routine doses hover near threshold levels, uncorrected depletion can create false confidence in stability.

Many dosimetry programs rely on the second read as a “confirmation” of the first, assuming close agreement implies validity. In reality, this can be an illusion of accuracy.

For Al₂O₃:C under strong-beam conditions using a YAG laser, the second-to-first read ratio remains stable across detectors, so a consistent 0.6 ratio feels reassuring. But that reproducibility reflects the physics of depletion, not the fidelity of the underlying dose record.

In contrast, BeO OSL systems use mathematical corrections that account for signal depletion per read.

When you perform a confirmation read with a BeO OSL system, you’re verifying the same corrected dose, not merely a predictable fraction of a diminished one.

This distinction is at the heart of dosimetry accuracy: the difference between consistent depletion and corrected dose integrity.

To achieve depletion correction, BeO OSL systems rely on a combination of empirical characterization and predictive modeling. Each read extracts a quantifiable fraction of the signal based on stimulation parameters (laser wavelength, beam energy, duration).

By modeling this extraction behavior (essentially, a depletion curve), the software applies inverse corrections to compensate for the lost signal. The result is a mathematically restored dose estimate that reflects the pre-read signal population.

In Al₂O₃:C systems, strong-beam protocols extract a much higher fraction of trapped charge in a single read. While reproducible, the depletion is too large for simple inverse correction without reintroducing significant uncertainty.

That’s why depletion handling – how signal extraction is modeled, corrected, and validated – is a technical differentiator in dosimetry system design.

| Al₂O₃:C (Strong-Beam with YAG Laser) | BeO OSL | |

| Material | Aluminum Oxide, Carbon-doped (Al₂O₃:C) | Beryllium Oxide (BeO) |

| Typical First-Read Loss | 40-70% | ~2.6% |

| Average Per-Read Loss | 15–20% | ~2.13% |

| Correction Applied | No | Yes |

| Accuracy at 100 mrem | ±40% (confirmation only) | ±2% (corrected) |

Table 1. Comparison of depletion handling and dosimetry accuracy between Al₂O₃:C and BeO OSL systems.

The choice between BeO OSL and Al₂O₃:C goes beyond just the material difference to consider organizational workflow, data integrity, and regulatory confidence.

BeO OSL’s low per-read depletion enables dose revalidation during audits, QA checks, or retrospective analyses without compromising signal integrity.

Accurate depletion correction ensures consistent readings across monthly exchanges, enabling RSOs to detect subtle exposure trends in staff populations.

With BeO’s corrected depletion, second reads truly confirm the same dose value, removing the ambiguity inherent in strong-beam Al₂O₃:C protocols using YAG laser.

Regulatory agencies, such as the US NRC, emphasize accurate dose reporting as a legal “dose of record.” Systems that inherently correct for depletion strengthen the defensibility of reported doses during audits and investigations.

Dosimetry accuracy considers calibration and comprehension. How a system handles depletion defines whether repeated readings confirm the dose or just confirm each other.

The BeO OSL approach demonstrates that depletion correction isn’t optional, it’s foundational. By minimizing signal loss and restoring accurate dose values through correction algorithms, BeO OSL enables confidence, repeatability, and audit-ready integrity in every read.

For radiation safety professionals, medical physicists, and health physicists alike, the takeaway is clear: in modern dosimetry, accuracy begins where depletion ends.

Depletion handling refers to how a dosimetry system accounts for the loss of signal during the readout process. Proper depletion handling, through modeling and correction, ensures accurate dose readings across multiple reads.

If uncorrected, depletion causes an underreporting of dose because a portion of the trapped signal is released during the first read. Systems that model and correct for depletion maintain consistent, accurate dose readings.

BeO OSL loses only about 2% of signal per read and applies correction algorithms, maintaining high dosimetry accuracy. In contrast, Al₂O₃:C under strong-beam stimulation loses 40-70% of signal without correction.

Yes, when used consistently and with awareness of depletion patterns, Al₂O₃:C systems remain reliable. However, the confirmation reads are reproducible, not corrective, so interpretation must reflect that limitation.

Systems with depletion correction, like BeO OSL, maintain traceable dose consistency across re-reads and time. This enables verifiable results during audits, inspections, and dose investigations.

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.