Dosimeter badge services for medical, dental, and veterinary businesses

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.

Senior Vice President of Operations & Technical Services

Last Updated: September 24, 2025

Understand what an X-ray dosimeter is, why they're important in radiation monitoring, and how to choose the right dosimetry device.

An X-ray dosimeter is a device used to measure and monitor the amount of radiation exposure someone may receive, typically in an occupational setting. There are different types of X-ray dosimeters available, each with its own features and capabilities.

Understanding the basics of how an X-ray dosimeter functions, why X-ray dosimeters are necessary, the differences between each type of dosimeter, and some best practices for radiation safety can go a long way in keeping people healthy, safe, and compliant. Keep reading to learn more.

The purpose of an X-ray dosimeter is to measure and monitor the radiation exposure levels experienced by individuals working in environments where radiation is present. These dosimeters play a crucial role in ensuring the safety of personnel by accurately quantifying the amount of radiation they are exposed to over a period of time.

Dosimeters capture radiation that provides valuable data to help individuals and companies in the form of exposure reports. These exposure reports offer more insight into occupational radiation for dentists, veterinarians, veterinary technicians, doctors, nuclear energy technicians, surgeons, and anyone else with occupational exposure to gamma or high energy beta radiation.

These essential devices are utilized across a wide variety of workplaces, including:

Different types of dosimeters are better suited for specific environments or roles – some are designed for first responders and emergency situations, while others are tailored for continuous monitoring in industrial settings or whole body tracking in healthcare facilities. This versatility ensures that whether you're working in a bustling hospital, a research laboratory, or responding to a natural disaster, there is a dosimetry solution designed to meet the unique demands of your environment.

X-ray dosimeters help employees and companies adhere to regulatory limits for radiation exposure and take necessary precautions to minimize risks to their health. While radiation monitoring requirements may differ from state to state, federal standards from the NRC limit whole body occupational total effective dose equivalent (TEDE) to 5,000 mrem per year.1

Radiation dose reports quantify the data measured by X-ray dosimeters, allowing individuals in occupational settings to implement necessary adjustments to radiation protection protocols, take action to address faulty machinery, and minimize the risk of health impacts related to radiation.

A control dosimeter serves as a reference device included in every shipment of X-ray dosimeters. Its main function is to detect background or incidental radiation exposure that might occur during shipping, storage, or handling, as opposed to exposure from actual occupational environments.

To use a control dosimeter, place it in a safe area away from sources of occupational radiation, ideally near the storage location of the other dosimeters but not worn by any individual. By comparing data from the control dosimeter to those worn by staff, dosimetry providers can distinguish genuine occupational exposure from any stray or incidental exposure encountered outside of the workplace. This ensures that exposure readings for employees remain accurate and reliable, supporting both compliance and the highest standards of safety monitoring.

Dosimetry companies provide regular badge exchanges to ensure ongoing, accurate monitoring. After each wear period, badges are sent to accredited laboratories for precise dose analysis. For example, RDC is accredited to provide dosimetry services with NVLAP, the National Voluntary Laboratory Accreditation Program (Lab Code 100512-0).

Users then receive standard dosimetry reports summarizing their exposure, which can be accessed and managed through customer portals, like MyRadCare™. These platforms allow organizations to easily track participants, manage badge assignments across multiple locations or departments, access historical reports, and keep tabs on unreturned or unused dosimeters. Many systems also provide shipment tracking, invoice management, and options for individual dose reviews, giving staff and administrators confidence in both compliance and safety.

In addition to standard monitoring, many organizations have access to a diverse set of specialized reports designed to provide deeper insights into radiation exposure management. These optional reports can support compliance initiatives, address specific workplace scenarios, and help organizations tailor their safety protocols more effectively.

Some commonly available optional and specialized dosimetry reports include:

Access to these optional reports allows organizations and professionals to tailor their monitoring and reporting practices, ensuring both regulatory compliance and optimal workplace safety.

Overall, X-ray dosimeters serve as essential tools in safeguarding the well-being of workers and maintaining a safe working environment in facilities where X-ray radiation is utilized. Understanding the differences between each X-ray dosimeter is essential to ensuring accurate measurement and monitoring of radiation exposure.

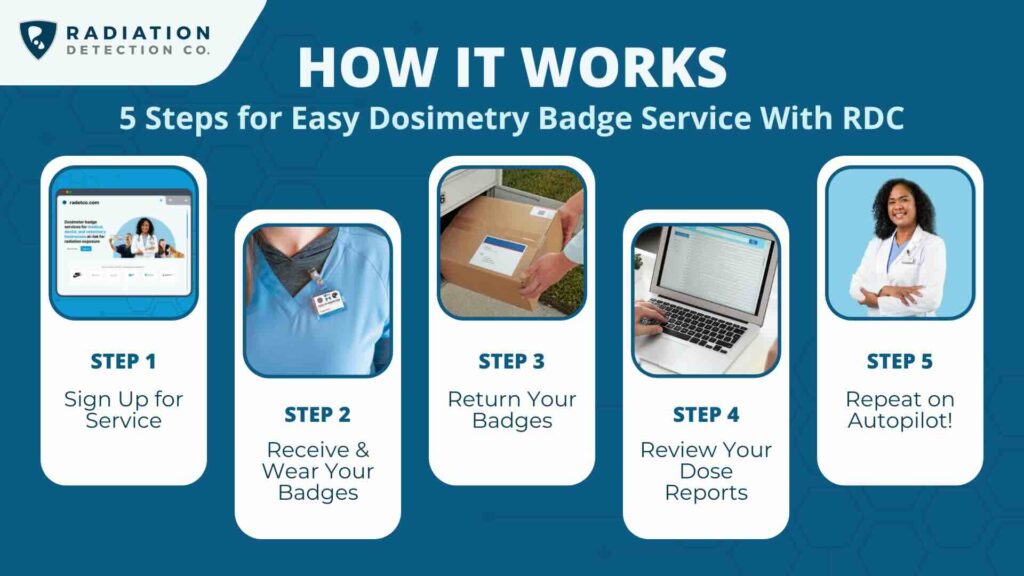

Effectively overseeing dosimeter programs involves a systematic approach to ensure accurate exposure tracking and regulatory compliance. Below is a quick rundown of what this process typically looks like in workplaces using radiation dosimetry badges.

Employees wear their assigned dosimeters for a set monitoring period – often a month, quarter, or year, depending on the facility’s policy and the regulatory body governing radiation safety. Dosimetry providers like Radiation Detection Company streamline this process by automatically mailing out new badges before the current period ends.

At the conclusion of the wear period, staff members remove their dosimeters and return them for analysis, usually using pre-paid mailing materials. These badges are then processed in accredited laboratories to ensure accurate measurement of cumulative radiation exposure.

After analysis, exposure data are compiled into easy-to-read reports, often featuring breakdowns by wear period, quarter-to-date, year-to-date, and lifetime-to-date dose equivalents. These reports commonly detail deep dose equivalent (for whole body), lens dose equivalent (for eyes), and shallow dose equivalent (for skin/extremities).

Professionals can access their exposure reports, manage badge assignments, track shipments, and maintain historical records through secure online portals. This centralized approach makes it easier to manage multiple locations, departments, and participants, while also offering features like shipment tracking, invoice management, and easy sharing of reports.

In addition to standard doses, optional reports – such as annual regulatory forms, fetal monitoring, ALARA (As Low As Reasonably Achievable) alerts, or exposure notifications – can be generated for specialized needs or compliance with NRC and state requirements.

By regularly reviewing dosimetry data, safety officers and managers can identify trends, catch potential issues with machinery, and implement adjustments to safety protocols as needed. Detailed exposure histories also help verify compliance and inform decisions on administrative controls or engineering upgrades.

Effectively managing dosimetry usage with established workflows, reliable reporting, and digital records not only supports regulatory adherence but also strengthens ongoing protection for everyone working around radiation sources.

There are several types of X-ray dosimeters available, each designed to measure and monitor radiation exposure in different ways.

Each type of dosimeter has its own advantages and disadvantages, and the choice of which one to use depends on the type of machinery used by professionals. Below, we've included some of the most common types of X-ray dosimeters.

One type of dosimeter is the film badge, which consists of a small piece of X-ray film enclosed in a protective holder. When exposed to X-rays, the film undergoes a chemical change that can be measured and analyzed to determine the amount of radiation exposure.

Film dosimeters use X-ray film to detect and measure radiation exposure. They are relatively inexpensive and easy to use, but they have limitations in terms of accuracy and sensitivity.

A thermoluminescent dosimeter is used to measure ionizing radiation, including gamma rays, x-rays, and beta radiation exposures. Thermoluminescent dosimeters use special crystals that can store energy when exposed to radiation. When stimulated later, the crystals can release this energy in the form of light, which can be measured to determine the amount of radiation exposure. TLDs are more accurate and sensitive than film badge dosimeters.

Optically stimulated luminescence dosimeters also use crystals to store energy when exposed to radiation. Both TLDs and OSLs capture point dose measurements, or radiation doses in a relatively small volume. However, instead of heating the dosimeter to release the energy, OSLs use light stimulation. OSLs are considered to be the most sensitive type of dosimeter, with a lower level of detection.

Other types of X-ray dosimeters include pocket ionization chambers, which use a small air-filled chamber to measure radiation exposure, and electronic personal dosimeters, which use electronic components to detect and measure radiation exposure.

The choice of which type of X-ray dosimeter to use depends on the type of machinery used in an occupational setting, the level of accuracy required, and the wearer's unique needs. For example, a pregnant veterinary technician will likely need to wear a fetal monitor in addition to a whole body dosimeter or a ring badge. It is important to select the appropriate dosimeter for each situation to ensure accurate measurement and monitoring of radiation exposure.

Certain dosimeters are specialized for unique work conditions. For instance, some are designed for emergency and first responders who may encounter unpredictable levels of radiation, while others are intended for industrial settings such as power plants or national laboratories, where sustained monitoring is critical. There are also versatile whole body dosimeters suitable for general occupational use in medical and research facilities.

Additionally, some dosimeters are purpose-built to measure specific types of exposure:

In certain scenarios, such as military operations or disaster response, dosimeters must be robust enough for rapid deployment and capable of recording sudden, high-dose events. Meanwhile, in fields like veterinary medicine, dental offices, or outpatient surgery centers, the emphasis might be on ease of use, comfort, and the ability to track cumulative exposure.

By understanding the strengths and intended applications of each type of dosimeter, employers and employees can make informed decisions to ensure accurate monitoring and enhanced safety in any radiation environment.

Learn more about the different types of dosimeters in this blog post: Dosimeters and their Differences: Active, Passive, and Digital Dosimeters

X-ray dosimeters and radiation safety are of utmost importance in various industries and professions where workers are exposed to radiation.

Excessive exposure to radiation can have harmful effects on the body, including an increased risk of cancer and other health problems. X-ray dosimeters play a crucial role in monitoring and controlling radiation exposure to ensure the safety of workers.

By wearing X-ray dosimeters, workers can track their radiation exposure levels and take appropriate measures to minimize their exposure. This may include wearing protective clothing, using shielding materials, or adjusting work practices to reduce the risk of overexposure.

In addition to protecting individual workers, X-ray dosimeters also help organizations comply with regulatory requirements related to radiation safety. Many industries, such as healthcare, nuclear power, and manufacturing, have strict guidelines and regulations in place to ensure the safety of workers and the public.

By using X-ray dosimeters and implementing proper radiation safety measures, organizations can create a safe working environment and minimize the risk of radiation-related incidents or health issues.

When selecting an X-ray dosimeter, there are several factors to consider to ensure it meets the specific requirements of the application and provides accurate measurements.

One important factor is the type of radiation that the dosimeter will be exposed to. Different dosimeters are designed to measure specific types of radiation, such as X-rays, gamma rays, or beta particles. It is essential to choose a dosimeter that is suitable for the specific radiation type that will be encountered.

Accuracy and sensitivity are also crucial factors to consider. The dosimeter should be able to provide reliable and precise measurements of radiation exposure. Calibration and regular maintenance of the dosimeter are essential to ensure its accuracy over time.

Other factors to consider include the size and comfort of the dosimeter, ease of use, durability, and cost. It is important to select a dosimeter that meets the specific needs and requirements of the application while also considering budget constraints.

Working with a company that prioritizes quality customer service can go a long way in keeping companies compliant and individuals safe. At Radiation Detection Company, we believe safety should be simple. That’s why we’ve provided dedicated, in-house customer service since 1949 – every time you call, you’ll speak to a real person from RDC.

Modern dosimetry management portals make it easier than ever to keep track of your team’s exposure and streamline administrative tasks. If you’re exploring software solutions to coordinate your dosimetry program, here’s what you can typically expect:

By leveraging these portal features, both small practices and large organizations can stay organized, compliant, and focused on safety – all with significantly less paperwork.

Not sure what dosimeter to choose? RDC can help. We'll walk you through each step to help you find the right badge service. Get started here.

Ensuring radiation safety is essential when working with X-rays or other sources of radiation. Here are some best practices to follow:

For dosimeters to provide accurate and reliable data, it’s important to handle, wear, and store them correctly from the moment they arrive on site. Typically, dosimeters will arrive in secure packaging, sometimes in separate bags for the dosimeters and their holders. Before a dosimeter is first worn, ensure any protective tabs or packaging are removed so the device can be properly read, and insert the dosimeter into its designated holder. If you're receiving your dosimeter badges from Radiation Detection Company, your dosimeters will arrive in the protective plastic case.

Placement of the dosimeter is crucial for accurate monitoring. Most commonly, dosimeters are worn on the chest to reflect whole body exposure, but placement may vary depending on workplace requirements or the specific type of monitoring needed (for example, fetal dosimeters are worn at the waist).

When not in use, dosimeters should be stored away from radiation sources, preferably on a designated badge board or in a central, low-radiation area. Proper storage prevents unintentional exposure and ensures that readings reflect only occupational exposure.

By following these best practices and taking some time to learn the basics of X-ray dosimeters – including correct wearing and storage procedures – individuals and organizations can minimize the risks associated with radiation exposure and create a safe working environment.

X-ray dosimeters measure radiation exposure by detecting ionization caused by X-rays in a material, converting it into an electrical signal. From there, a radiation detection company will tabulate the results in a radiation report that includes detailed information about exposure levels, ensuring safety in environments where X-ray equipment is used.

Dosimeters are used to monitor and measure an individual's exposure to radiation, ensuring that they do not exceed safe levels of exposure and helping to prevent potential health risks associated with overexposure to radiation.

A radiation detector detects ionizing radiation levels. Dosimeters are a type of radiation detector; they specifically measure and record absorbed dose for an individual working in an environment where radiation is present.

Radiation dosimetry measures and monitors the amount of radiation absorbed by individuals or objects. Radiation dosimetry helps ensure radiation safety in various fields (such as medicine, industry, research, and nuclear energy) by preventing overexposure and assessing potential health risks.

At the end of each wear period – whether monthly, quarterly, or annually – your dosimetry provider should deliver a fresh set of dosimeters to your workplace about two weeks in advance. This allows for a smooth transition with no gaps in monitoring. When the current wear period ends, you simply swap out your old dosimeters for the new ones.

To return the used badges:

The provider will read and analyze your badges, then compile the exposure data into a detailed report. This routine exchange ensures continuous, accurate monitoring of workplace radiation exposure and keeps organizations compliant with safety regulations.

Learn how Radiation Detection Company’s easy-to-use dosimetry solutions can boost the efficiency of your practice.